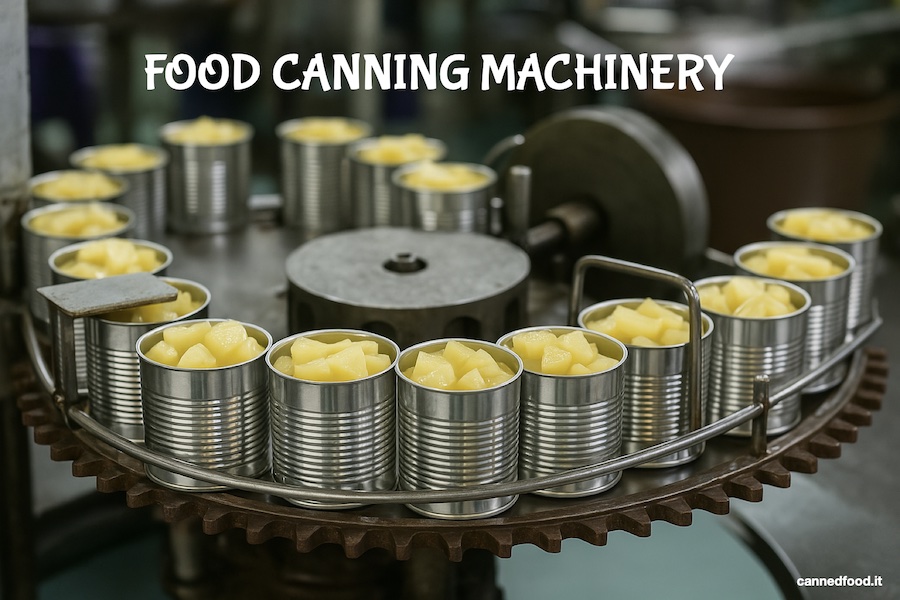

Food canning machinery refers to equipment designed for preserving food by sealing it in airtight containers, typically cans or jars. The process involves sterilizing food, filling containers, sealing them, and sometimes pasteurizing the sealed product to ensure long shelf life.

Key Components of Food Canning Machinery

1. Sorting and Cleaning Machines

- Removes debris, dirt, and damaged products.

- Examples: Rotary washers, air-blast cleaners.

2. Preparation Equipment

- Includes cutting, slicing, peeling, or blanching machines.

- Essential for fruits, vegetables, and meats.

3. Filling Machines

- Precisely fill cans with solid, liquid, or semi-liquid products.

- Types: Gravity fillers, piston fillers, vacuum fillers.

4. Sealing Machines

- Ensures airtight closure for preservation.

- Types: Vacuum sealers, double seamers, twist-off cappers.

5. Sterilization Machines

- Kills bacteria to extend shelf life.

- Methods: Steam, hot water, or retort sterilization.

6. Cooling Systems

- Cools down sealed cans to prevent overcooking.

- Examples: Water cooling tunnels or air-blast coolers.

7. Labeling and Coding Machines

- For product branding and batch coding.

- Types: Heat transfer, inkjet, or laser coders.

8. Inspection Systems

- Ensures quality control through visual inspection or X-ray scanning.

9. Packaging Machines

- Wraps canned food for transport and retail presentation.

- Examples: Shrink wrappers, carton sealers.

Types of Food Canning Machinery

1. Manual Canning Machines

- Suitable for small-scale operations and home-based businesses.

2. Semi-Automatic Canning Machines

- Partially automated, ideal for medium-scale businesses.

3. Fully Automatic Canning Machines

- High-speed systems designed for industrial-scale production.

Popular Manufacturers of Canning Machinery

- Krones AG (Germany)

- Tetra Pak (Switzerland)

- Ferrum AG (Switzerland)

- JBT Corporation (USA)

- Lanico Maschinenbau (Germany)

- Hermasa (Spain)

- Dixie Canner Co. (USA)

Trends in Canning Machinery Industry

- Automation & Robotics: Enhanced precision and efficiency with automated filling, sealing, and labeling.

- Sustainability Focus: Machines optimized for energy savings and minimal environmental impact.

- IoT Integration: Real-time monitoring and predictive maintenance for improved productivity.

- Flexible Packaging Solutions: Adaptable machinery for diverse product types and packaging styles.